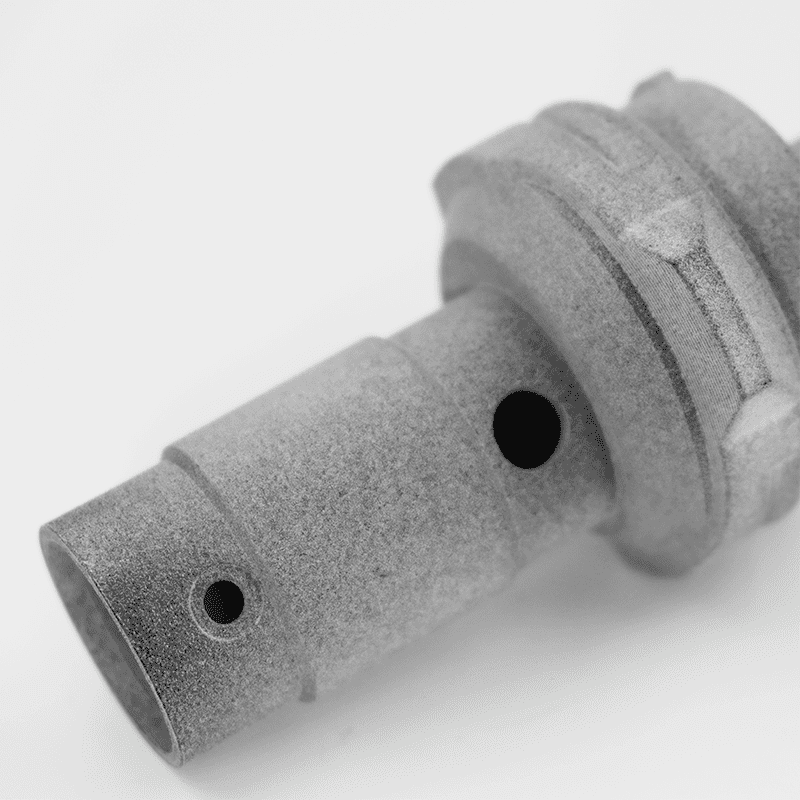

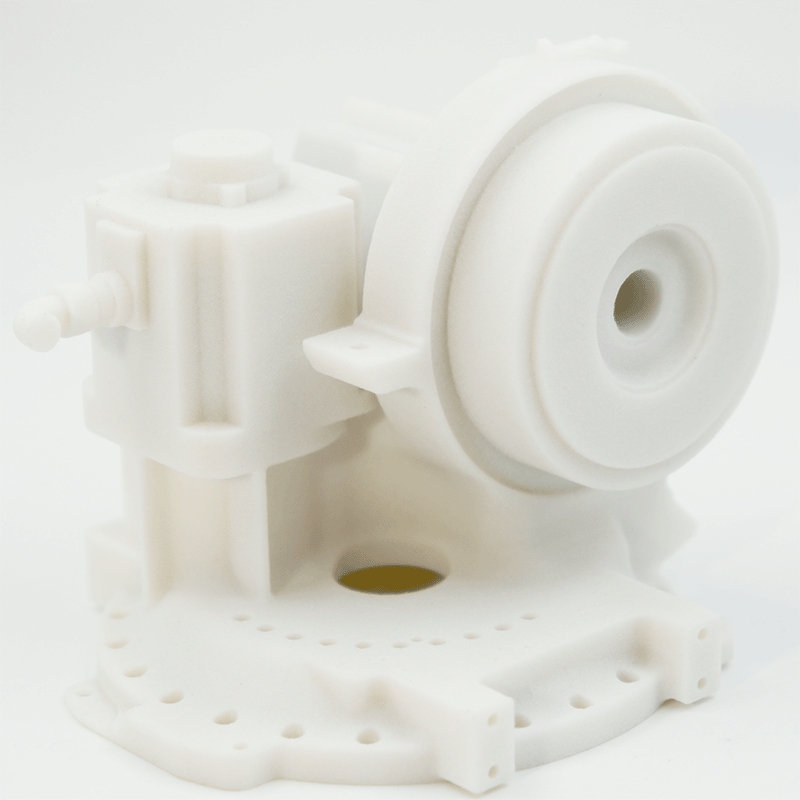

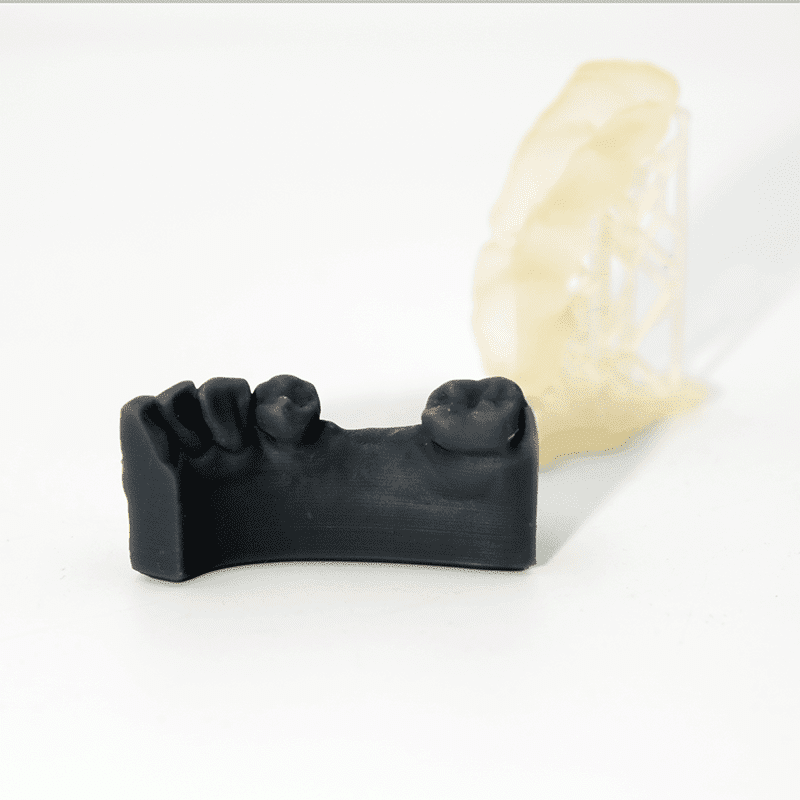

Multi Jet Fusion (MJF) is an advanced 3D printing process that can speedily produce accurate, complex and detailed parts from powdered thermoplastics. MJF parts have high tensile strength and fine feature resolution, making them perfect for complex industrial parts. Developed by HP, this relatively new 3D printing technology is perfect for creating functional prototyping and ......