-

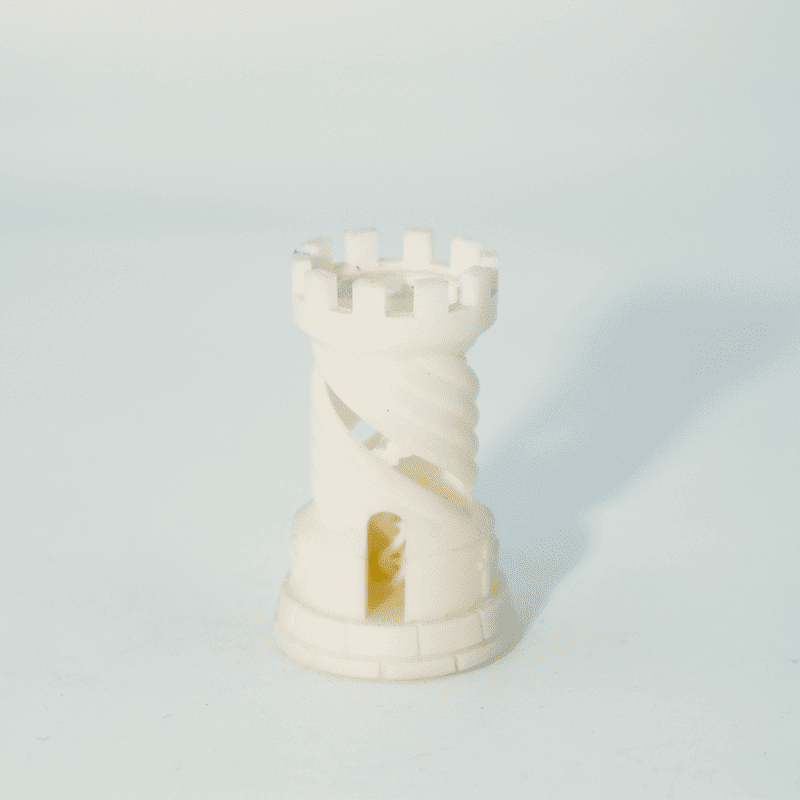

White resin

Stereolithography (SLA), also known as resin 3D printing, is a 3D printing technology that produces parts with high resolution and accuracy, fine details and smooth surface finishes. Part of the vat photopolymerization printing family, SLA technology uses photosensitive thermoset polymers to produce custom parts. We use Formlabs materials for rapid prototyping and 3D Systems Accura materials for large-scale production.

SLA is most suitable for visual applications where an injection mold-like, smooth surface finish, and a high level of feature detail are required.Fine features & high detail,Smooth,injection mold-like,surface finish.Support marks may be visible on surface,Brittle,not recommended for functional parts

View details -

High toughness resin

High toughness material , capable of drilling and screwing

High precision and good surface effect

Featuring excellent detail presentation, low shrinkage rate, good dimensional stability, durability, heat resistance, able to meet painting requirements, suitable for components that resist high-strength impact and shock absorption.

View details -

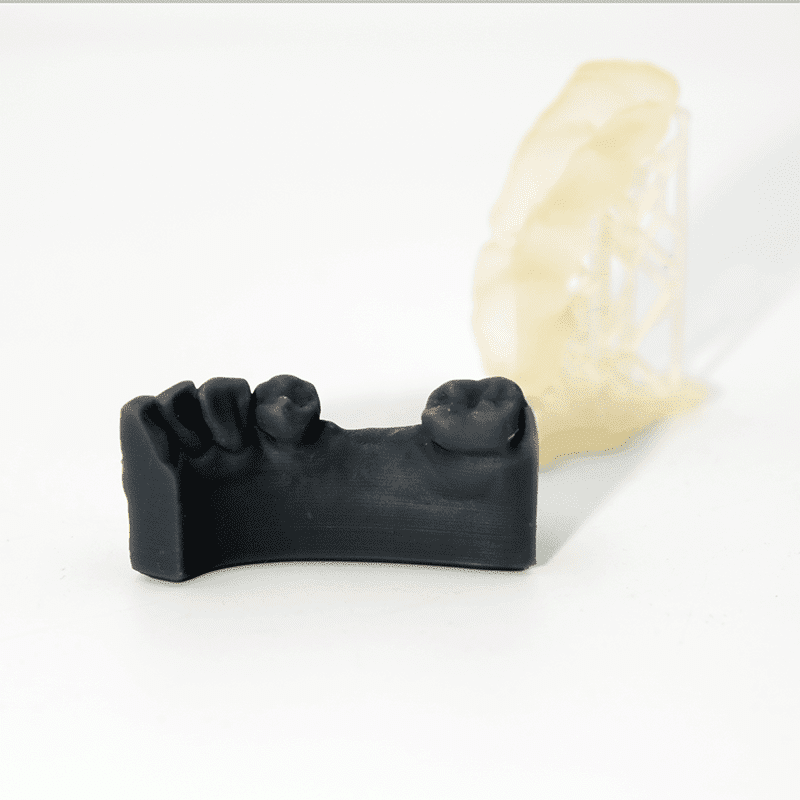

Clear resin

This clear reisn is semi-clear, rigid, watertight, and suitable for 3D printing parts with great resolution and detail, offering smooth surfaces, and few layer lines.

Also known as Clear Plastic, Clear SLA, or Translucent Resin, customers use this material for tech accessories, lighting components, casting patterns, snap-fit assemblies, and prototypes and models.

SLA Plastic is recommended for SLA 3D printing projects that require complex functional assemblies which also require transparency. Offered in a standard, semi-clear finish, products are sanded lightly to remove any nubs from support removal. There may also be slight variations in clarity and texture over the surface of the model, depending on print orientation and post-processing. Further optical clarity can be achieved in post-processing too, but that is generally not included with standard orders.

View details