-

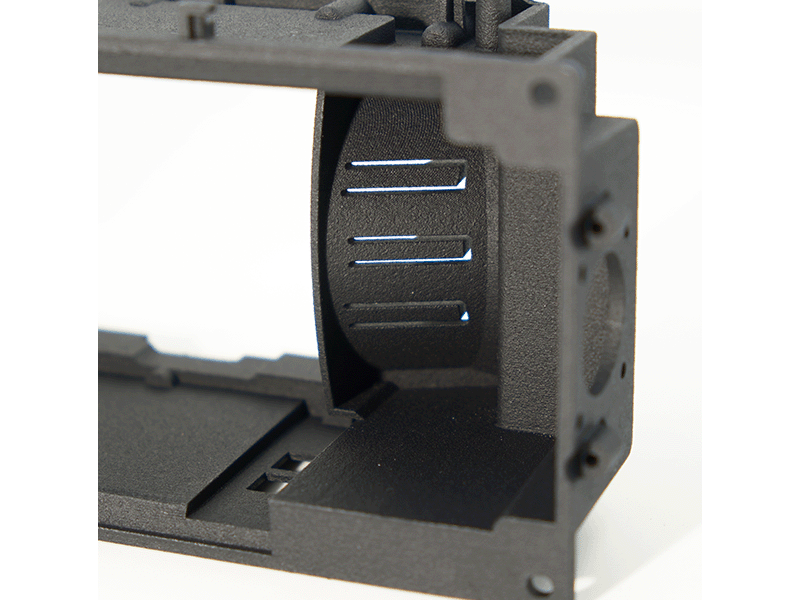

MJF PA12

This material is commonly relied on for superior strength and elasticity, making it suitable for highly functional parts. MJF PA12 parts are also chemical- and water-resistant.

View details -

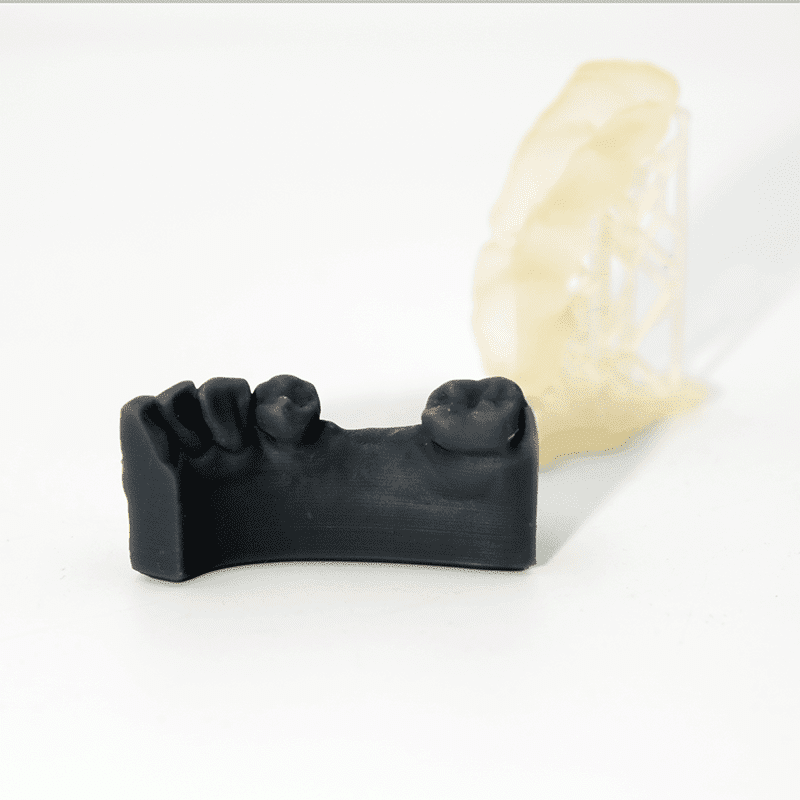

SLS white nylon

Nylon 12 [Versatile Plastic] is a strong polyamide relied on worldwide for industrial products. This material truly lives up to its name, setting it apart from other materials due to its ability to act flexible for thinner structures and moving mechanical parts, but also rugged and stiff for substantial, end-use parts in applications like jewelry, architectural designs and home decor, fixtures, and prosthetics.

Nylon 12 [Versatile Plastic] is also porous enough to allow for dyeing, with a wide range of colors available for parts and prototypes.

View details -

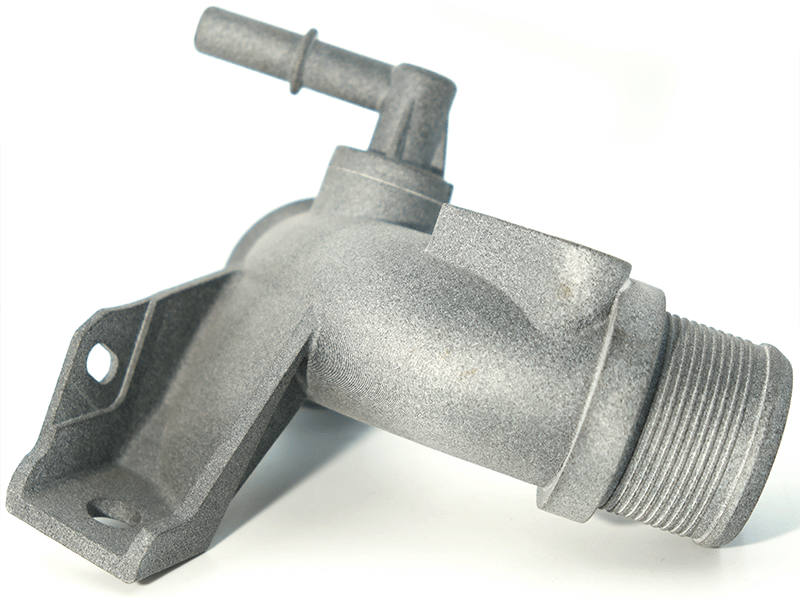

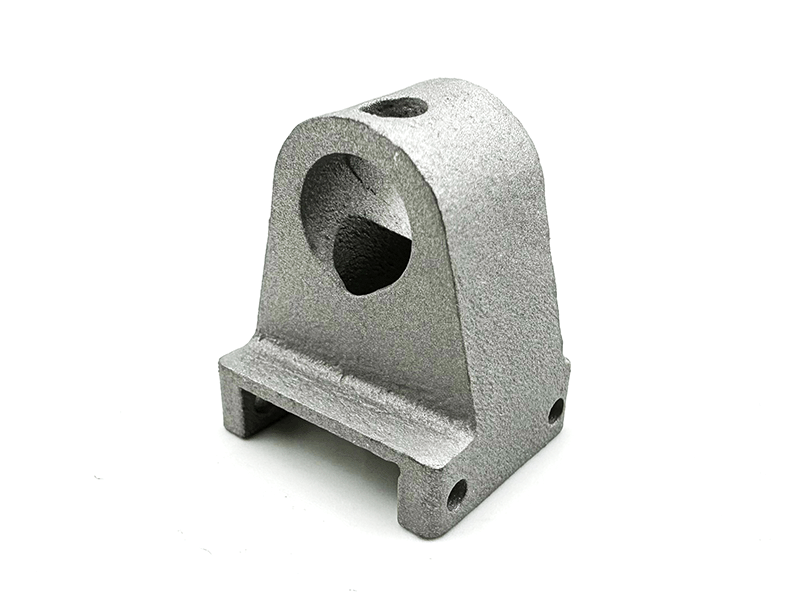

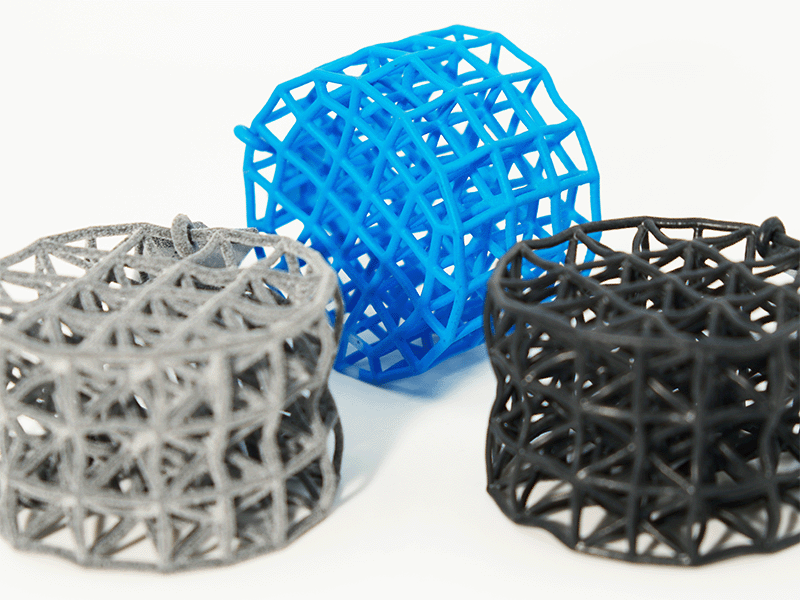

Stainless Steel ( 316L )

Metal 3D printing, an additive manufacturing process, produces parts by fusing together metal particles layer by layer to form a metal part. It is often chosen as an alternative to CNC machining or metal casting because it can produce parts with the strength and durability of metal while also taking advantage of the design freedoms afforded by 3D printing. It can produce complex designs including lattices and topology-generated structures, both which are impossible to manufacture via traditional CNC machining.

View details -

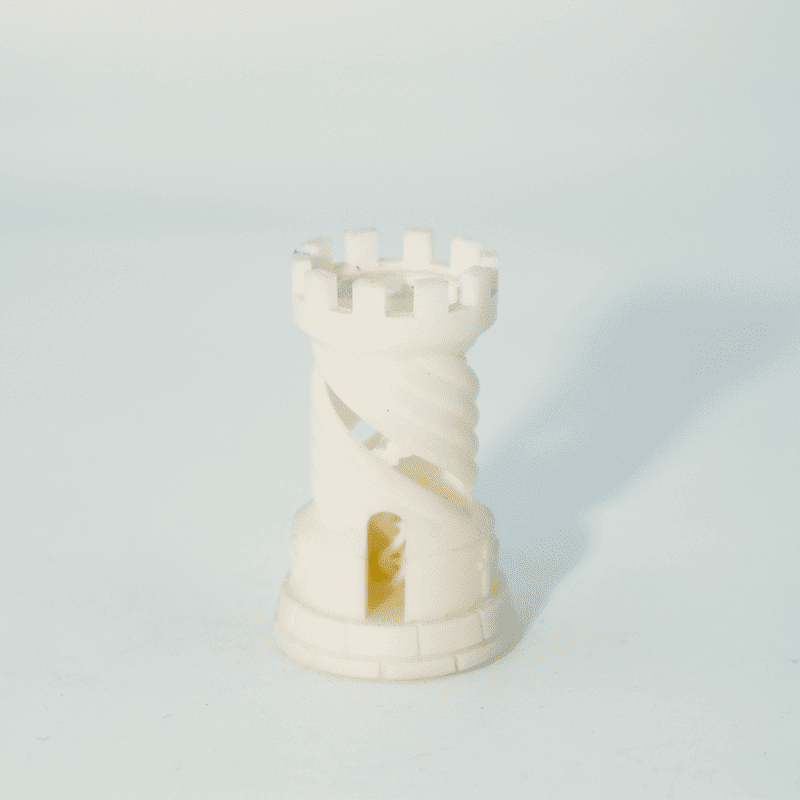

White resin

Stereolithography (SLA), also known as resin 3D printing, is a 3D printing technology that produces parts with high resolution and accuracy, fine details and smooth surface finishes. Part of the vat photopolymerization printing family, SLA technology uses photosensitive thermoset polymers to produce custom parts. We use Formlabs materials for rapid prototyping and 3D Systems Accura materials for large-scale production.

SLA is most suitable for visual applications where an injection mold-like, smooth surface finish, and a high level of feature detail are required.Fine features & high detail,Smooth,injection mold-like,surface finish.Support marks may be visible on surface,Brittle,not recommended for functional parts

View details -

High toughness resin

High toughness material , capable of drilling and screwing

High precision and good surface effect

Featuring excellent detail presentation, low shrinkage rate, good dimensional stability, durability, heat resistance, able to meet painting requirements, suitable for components that resist high-strength impact and shock absorption.

View details -

Clear resin

This clear reisn is semi-clear, rigid, watertight, and suitable for 3D printing parts with great resolution and detail, offering smooth surfaces, and few layer lines.

Also known as Clear Plastic, Clear SLA, or Translucent Resin, customers use this material for tech accessories, lighting components, casting patterns, snap-fit assemblies, and prototypes and models.

SLA Plastic is recommended for SLA 3D printing projects that require complex functional assemblies which also require transparency. Offered in a standard, semi-clear finish, products are sanded lightly to remove any nubs from support removal. There may also be slight variations in clarity and texture over the surface of the model, depending on print orientation and post-processing. Further optical clarity can be achieved in post-processing too, but that is generally not included with standard orders.

View details -

PA12GB

This unique material is filled with 40% glass beads, offering superior stiffness, and also helping to prevent warping in larger or flatter parts. MJF PA12GB is also used for applications that require great strength, to include:

- Tooling

- Robotics

- Drones

- Medical braces

- Housings and cases

View details -

PA11

Nylon 11 is a robust polyamide offering great tensile strength, durability, impact resistance, and flexibility. Due to its biocompatibility, Nylon 11 [PA11(SLS)] is uniquely suited for manufacturing the following:

- Exterior medical devices

- Automotive parts

- Sports equipment

- Loaded functional prototypes

- Hinges

View details -

Aluminium Alloy ( AlSi₁₀Mg )

Metal 3D printing, an additive manufacturing process, produces parts by fusing together metal particles layer by layer to form a metal part. It is often chosen as an alternative to CNC machining or metal casting because it can produce parts with the strength and durability of metal while also taking advantage of the design freedoms afforded by 3D printing. It can produce complex designs including lattices and topology-generated structures, both which are impossible to manufacture via traditional CNC machining.

View details -

Titanium Alloy ( TC4 )

Metal 3D printing, an additive manufacturing process, produces parts by fusing together metal particles layer by layer to form a metal part. It is often chosen as an alternative to CNC machining or metal casting because it can produce parts with the strength and durability of metal while also taking advantage of the design freedoms afforded by 3D printing. It can produce complex designs including lattices and topology-generated structures, both which are impossible to manufacture via traditional CNC machining.

View details -

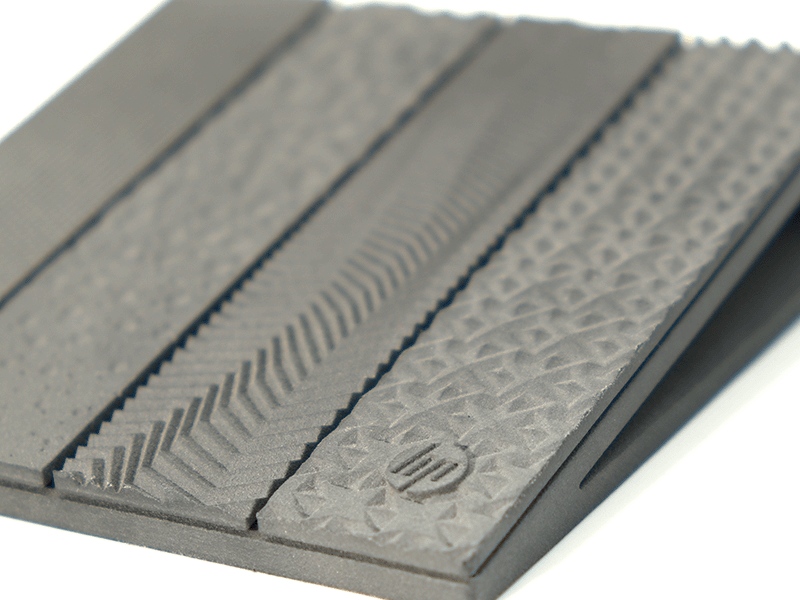

3D printing MJF TPU

TPU (MJF) is a high-performing thermoplastic polyurethane (TPU) powder, enabling the production of elastomeric functional parts with the advantages of additive manufacturing, obtaining similar performance as injection molding. The parts made from TPU (MJF) are flexible, tough, and provide high elongation and impact resistance for applications such as soft grip systems, footwear, seating and protective gear. It’s also well-suited for soft non-marring tooling, flexible tubing, wheels and ducts. Parts printed from TPU (MJF) are gray naturally, and black when dyed or smoothed.

View details -

3D printing MJF PP

Polypropylene (PP) is a versatile material ideal for a wide range of automotive, consumer, industrial and medical applications. With its excellent chemical resistance, low moisture absorption and long-term durability, HP High Reusability PP enabled by BASF is ideal for piping, fluid systems and containers. The versatility of this PP material enables the production of prototypes and final parts offering the same properties as PP for injection molding.

View details