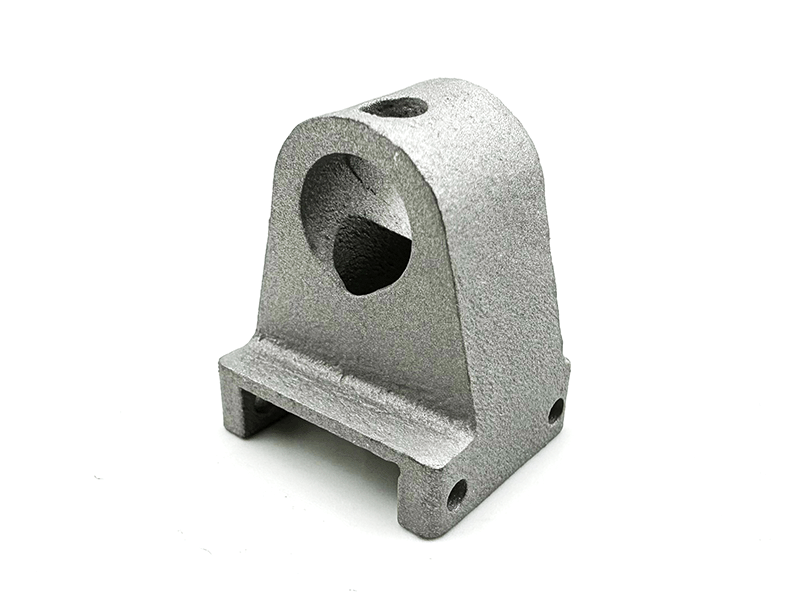

Metal 3D printing, an additive manufacturing process, produces parts by fusing together metal particles layer by layer to form a metal part. It is often chosen as an alternative to CNC machining or metal casting because it can produce parts with the strength and durability of metal while also taking advantage of the design freedoms afforded by 3D printing. It can produce complex designs including lattices and topology-generated structures, both which are impossible to manufacture via traditional CNC machining.

Die Steel ( MS1 )

|

PHYSICAL CHARACTERISTICS |

Grain Size15~53μm ShapeSpherical Mobility40S(Hall flowmeter) Apparent density4.3 g/cm³ |

|

CHEMICAL COMPOSITION |

Fe(Balance) Cr(8.5~9.5%) Ni(17~19%) Mo(4.2~5.2%) Mn(≤0.1%) Ti(≤0.8~0.9%) C(≤0.03%) Al(≤0.05~0.15%) S(≤0.01%) O(≤0.15%) |

|

MOLDING PERFORMANCE |

Relative Density≥99% Density8 g/cm³ Tensile Strength≥1090 MPa Yield strength≥1000 MPa Elongation at break10 %(thermal process : 4%) Elastic Modulus160 GPa(thermal process : 180 GPa) Hardness323 HB(thermal process : 585 GPa) |

Copyright © 2021